-

Inversor solar de la bomba la monofásico

-

Inversor solar de la bomba de 3 fases

-

Inversor solar de la bomba de MPPT VFD

-

Regulador solar de la bomba de agua

-

Impulsión variable de la frecuencia de VFD

-

Inversores variables de la frecuencia

-

Inversor de PMSM

-

220v entrado inversor hizo salir 380v

-

Arrancador suave del motor

-

Reactor del inversor

-

Resistor de frenado de VFD

-

Filtro de VFD

-

Tayfun de TurquíaEl inversor solar de la bomba de Veikong está realmente en calidad muy buena y también preparamos algunos productos promocionales para la exposición. Vamos a hacer nuevas órdenes pronto. Había el año pasado solamente un agente local y este año, hay más de 8. ¡Algunos de ellos solamente vender Veikong!

Tayfun de TurquíaEl inversor solar de la bomba de Veikong está realmente en calidad muy buena y también preparamos algunos productos promocionales para la exposición. Vamos a hacer nuevas órdenes pronto. Había el año pasado solamente un agente local y este año, hay más de 8. ¡Algunos de ellos solamente vender Veikong! -

Cristian de Chile¡Es muy bueno! Las opciones del LCD hacen mucho más fácil utilizar. Ése es el punto fuerte, fácil de uso. Y robusto. Gran software de la PC.

Cristian de Chile¡Es muy bueno! Las opciones del LCD hacen mucho más fácil utilizar. Ése es el punto fuerte, fácil de uso. Y robusto. Gran software de la PC. -

Brahim assad de SiriaLa frecuencia de la salida de VEIKONG VFD500 es estable cuando están fluctuando las otras. También la corriente de salida es menos que otras, por eso la frecuencia de la salida son más altas también que puede ahorrar más energía.

Brahim assad de SiriaLa frecuencia de la salida de VEIKONG VFD500 es estable cuando están fluctuando las otras. También la corriente de salida es menos que otras, por eso la frecuencia de la salida son más altas también que puede ahorrar más energía.

| Lugar de origen | Porcelana |

|---|---|

| Nombre de la marca | VEIKONG |

| Certificación | CE IEC |

| Número de modelo | VFD510 |

| Cantidad de orden mínima | 23 PC |

| Detalles de empaquetado | Caja de papel o madera |

| Tiempo de entrega | Depender de la cantidad |

| Condiciones de pago | Moneygram, Western Union, T/T |

| Capacidad de la fuente | 1000 por mes |

| OEM | Compatible | Motor o bomba adecuados | PM y IMSM |

|---|---|---|---|

| Rango de potencia | 4KW a 45KW | Mostrar | Display LCD/LED y de transporte para opciones |

| Aplicación | General | Método de enfriamiento | Enfriamiento del aire forzado |

| Período de garantía | 24 meses | Peso | Dependiendo de la potencia nominal |

| Opciones de la exhibición | LCD, LED, modelo nuevo LCD | Estándar o no estándar | Estándar |

| Certificaciones | CE, UL, ROHS | Nivel de protección | IP55 |

| Destacar | Inverter de control de vectores IP55, inversor Veikong VFD510, Motores Síncronos Magnet Permanentes |

VEIKONG VFD510: Un variador vectorial IP55 de alto rendimiento para un control óptimo de PMSM.

1. Introducción del nuevo modelo de la serie VEIKONG VFD510:

¡Presentamos el innovador inversor de alta protección de la serie VFD510, su solución para entornos desafiantes! Con un impresionante grado de protección IP55, este inversor está diseñado específicamente para prosperar en entornos con exceso de polvo, aceite y niebla de agua. Con una versión mejorada de la serie líder VElKONG VFD530, el VFD510 conserva una calidad excepcional y ahora ofrece funciones de alta protección adicionales.

Este inversor de alta gama es versátil y puede accionar tanto motores asíncronos como motores síncronos de imanes permanentes. Viene con una función STO estándar y admite una variedad de tipos de codificadores e interfaces de comunicación, lo que proporciona flexibilidad y conveniencia.

Nuestra serie VFD510 no solo ofrece un rendimiento y una fiabilidad excelentes, sino que también está repleta de funciones para que destaque entre la multitud. Quedará impresionado con sus ricas capacidades funcionales y su capacidad para adaptarse a una variedad de condiciones ambientales.

Invierta en el inversor de la serie VFD510 y manténgase a la vanguardia, sin importar el entorno.

![]()

2. Tabla de selección de producción

| Modelo de inversor | Capacidad nominal (KVA) | Corriente de entrada nominal (A) | Corriente de salida nominal (A) | Motor aplicable (kw) | Tamaño estructural | Unidad de frenado | |

| Carga pesada | |||||||

| VFD510-4R0-T4B | 5.9 | 10.5 | 9.4 | 4kw | TAMAÑO A | Incorporado | |

| VFD510-5R5-T4B | 8.9 | 14.6 |

13.0 |

5.5kw | |||

| VFD510-7R5-T4B | 11 | 20.5 | 17.0 | 7.5kw | TAMAÑO B | ||

| VFD510-011-T4B | 17 | 26.0 | 25.0 | 11kw | |||

| VFD510-015-T4B | 21 | 35.0 | 32.0 | 15kw | TAMAÑO C | ||

| VFD510-018-T4B | 24 | 38.5 | 37.0 | 18.5kw | |||

| VFD510-022-T4B | 30 | 46.5 | 45.0 | 22kw | |||

| VFD510-030-T4(B) | 40 | 62.0 | 60 | 30kw | TAMAÑO D | ||

| VFD510-037-T4(B) | 50 | 76.0 | 75 | 37kw | |||

| VFD510-045-T4(B) | 60 | 92.0 | 90 | 45kw |

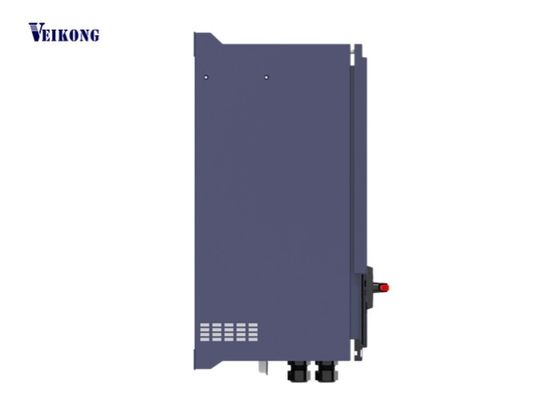

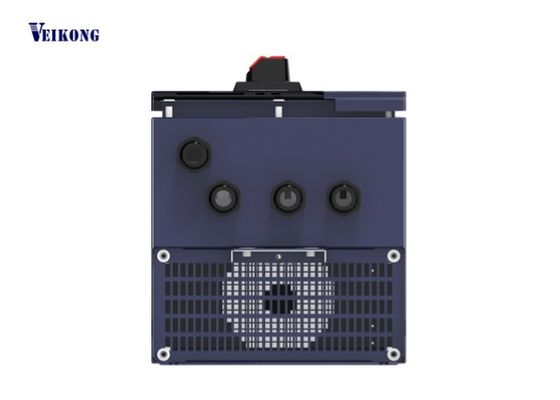

3. Tamaño del producto VEIKONG y visualización de todos los lados

![]()

![]()

3. Las características de la nueva serie VEIKONG VFD510 IP55

1) Diseño de conducto de aire independiente

El diseño de conducto de aire independiente evita eficazmente que el polvo entre en el inversor y cause cortocircuitos y otras fallas, mejorando así la fiabilidad;

El uso de un ventilador de refrigeración de gran volumen de aire y larga vida útil reduce eficazmente el aumento de la temperatura interna del inversor y garantiza un funcionamiento fiable y estable del inversor.

2) Sistema de protección completo

Toda la serie tiene protección STO, protección contra cortocircuitos de salida a tierra, protección contra sobrecorriente, protección contra sobrecarga del controlador, protección contra sobrecarga del motor, protección contra sobretemperatura del controlador, protección opcional contra sobretemperatura del motor PT100/PT1000/KTY84, etc.

Dependiendo del tipo de fallo, se puede configurar para parada sin fallo, parada por deceleración por fallo, funcionamiento continuo por fallo, lo que aporta comodidad a la gestión de emergencias in situ.

3) Proceso de pulverización automática de revestimiento conformable

Se utilizan múltiples revestimientos conformables de alta calidad para mejorar la adaptabilidad ambiental del producto.

El revestimiento conformable adopta un proceso de pulverización automática para garantizar la uniformidad del grosor de la pulverización de la placa de circuito y la consistencia de la dosificación del producto.

4) Amplio rango de entrada de voltaje que cumple con los estándares internacionales

Tensión nominal

Rango de fluctuación de voltaje permitido

Potencia de entrada

frecuencia

Modelos monofásicos/trifásicos de 220 V 200 V~240 V

Modelos trifásicos de 380 V: 380 V~480 V

-15%-10%

50 Hz o 60 Hz. rango de fluctuación permitido +5%

5) Experimento de simulación de diseño térmico

El software de plataforma de simulación térmica precisa se utiliza para garantizar la fiabilidad de la simulación térmica. Los inversores de la serie VFD510 se han sometido a pruebas de simulación térmica. Solo dentro de los requisitos de diseño de seguridad de la simulación térmica, se desarrollan prototipos físicos. Después de las pruebas reales, los resultados de la simulación térmica son muy cercanos a los resultados de las pruebas físicas. En condiciones de prueba extremas, la simulación térmica puede reemplazar la simulación de carga real, agregando una capa adicional de pruebas térmicas científicas.

6) Estricta prueba de aumento de temperatura

La prueba de aumento de temperatura de toda la unidad adopta la prueba de sobrecarga cíclica más estricta para garantizar un funcionamiento fiable a largo plazo en condiciones de carga extrema.

Prueba de sobrecarga cíclica: A una temperatura ambiente de 50°, funcionar a 1,5 veces la corriente de sobrecarga durante 1 minuto, luego funcionar a la corriente nominal durante 4 minutos y luego funcionar a 1,5 veces la corriente nominal durante 1 minuto. Este ciclo continuo funciona durante 5 minutos por ciclo hasta que el sistema alcanza un estado de equilibrio térmico y toda la unidad se encuentra dentro del rango de seguridad del diseño térmico.

7) Pruebas de ciclo completo

Durante el desarrollo del producto, toda la placa de circuito impreso se probará sistemáticamente. Después del montaje, se probará toda la máquina y se probará el entorno EMC. Después de pasar el control de calidad, se realizará una prueba de envejecimiento a alta temperatura de 12 horas y 50°C para garantizar la calidad de entrega de toda la serie de productos.

![]()

Inversor vectorial PMSM de 0,4 kW

Inversor de alta eficiencia para PMSM